Guangzhou Risong Hokuto Automotive Equipment Co., Ltd. is one of the earliest companies in China to provide intelligent solutions for automotive equipment, and is also the largest R&D manufacturer of automotive intelligent equipment and technology in China. It provides overall turnkey engineering services for automotive manufacturing, including preliminary process solution analysis, whole-line planning, design, manufacturing, commissioning and installation. It has been serving well-known automobile enterprises such as GAC Group, Changan Group, Toyota, Honda, Mitsubishi, Mazda, GAC Motor, Geely Auto, GAC Aion, BYD, Xpeng Motors, Hycan, Leapmotor, and EEZI for a long time.

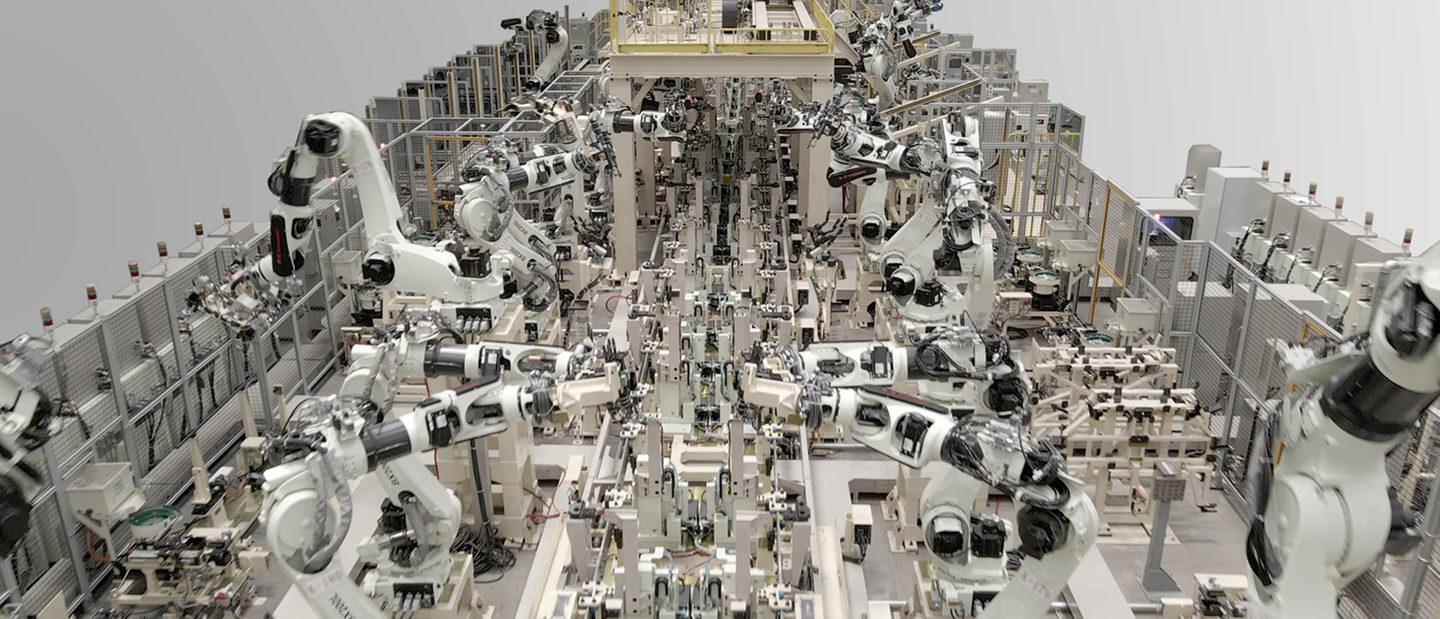

Based on the nearly 50 years of technical foundation of Hokuto from Japan, Risong Hokuto has accumulated a large number of innovative technical achievements and proven project experience in the field of automobile intelligent manufacturing, and has comprehensive capabilities covering process flow planning, whole-line layout, style formulation, 3D design, 3D dynamic simulation, drawing design and offline program output.

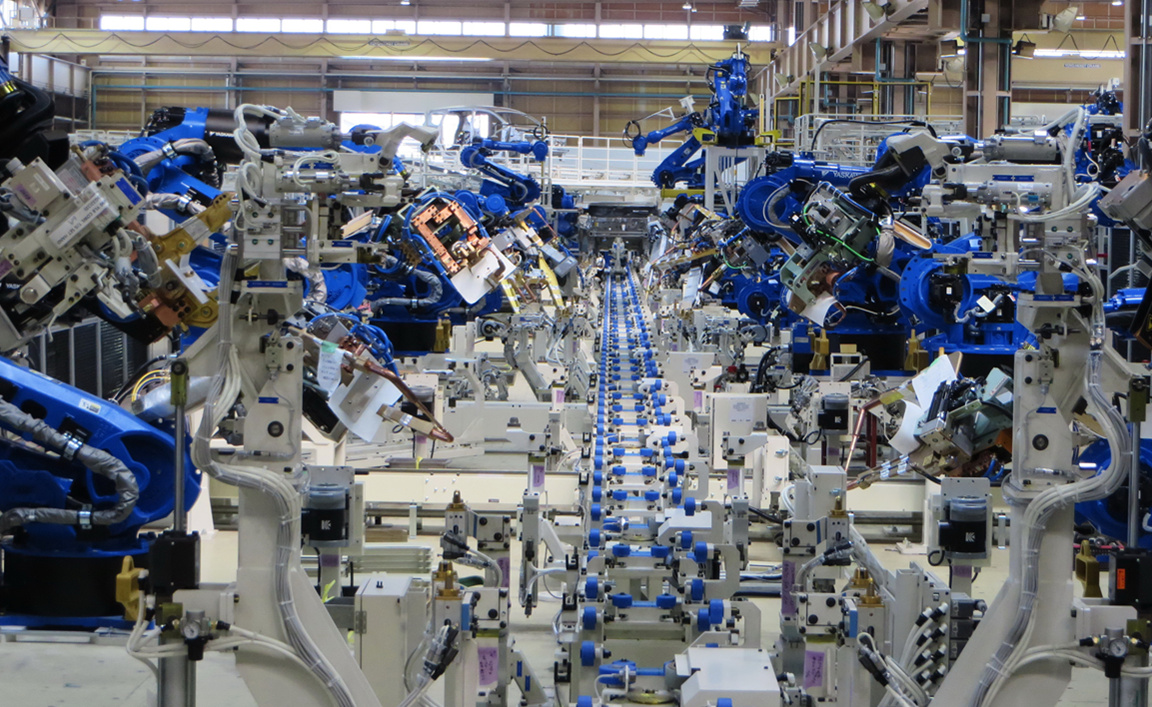

● Risong Hokuto is the core supplier of Toyota's first overseas factory of the latest TNGA platform, and has helped GAC Toyota become one of Toyota's global model factories;

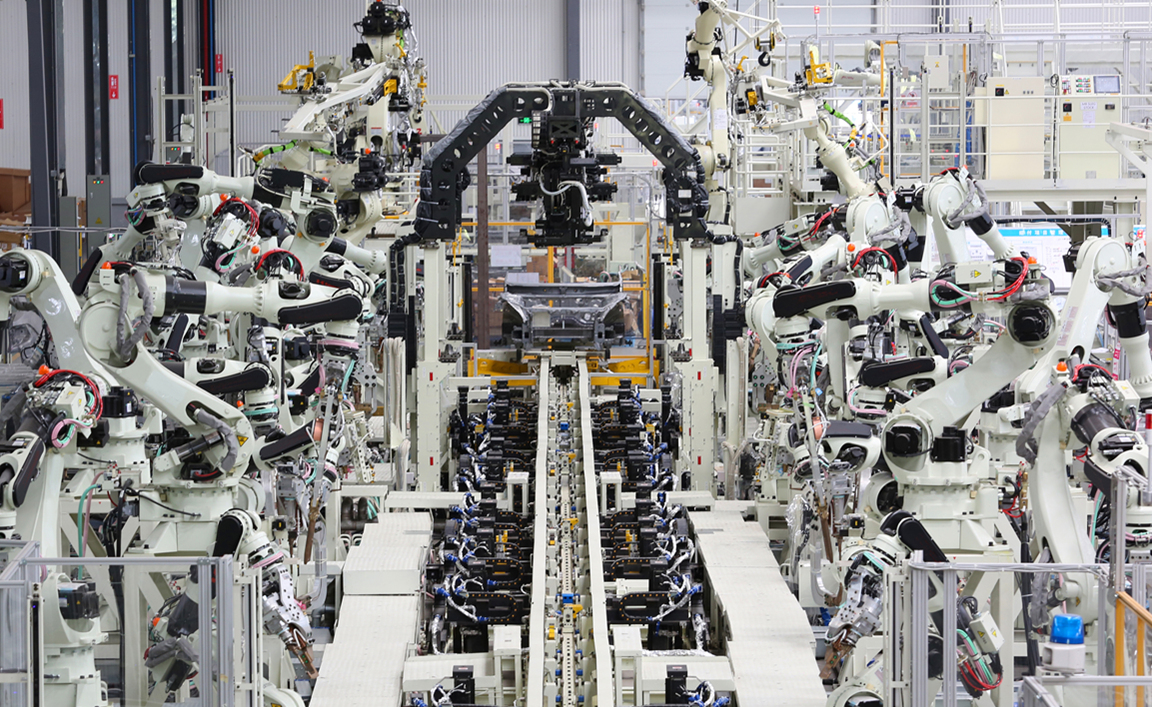

● With Risong Hokuto's capacity, for the first time, the independent brand GAC MOTOR has realized unmanned production of the whole production line, and its efficiency and intelligent flexibility of the production line have reached the world leading;

● Risong Hokuto provides the self-owned brand GAC NEV with technical support for its production of lightweight aluminum body for the first time, successfully breaking the technical blockade of international giants in this field;

● The four-door and two-cover assembly line provided for Mazda Automobile is the first flexible intelligent door assembly and commissioning line independently developed and mass-produced in China. It sets a model of international advancement.