High Efficiency

Applying VR to new production lines (currently digital models only) will enable faster training of operators, workers, and maintenance personnel and reduce line installation time. The workers will arrive at the new production line with layout and production work already in their minds, so that the efficiency will be improved.

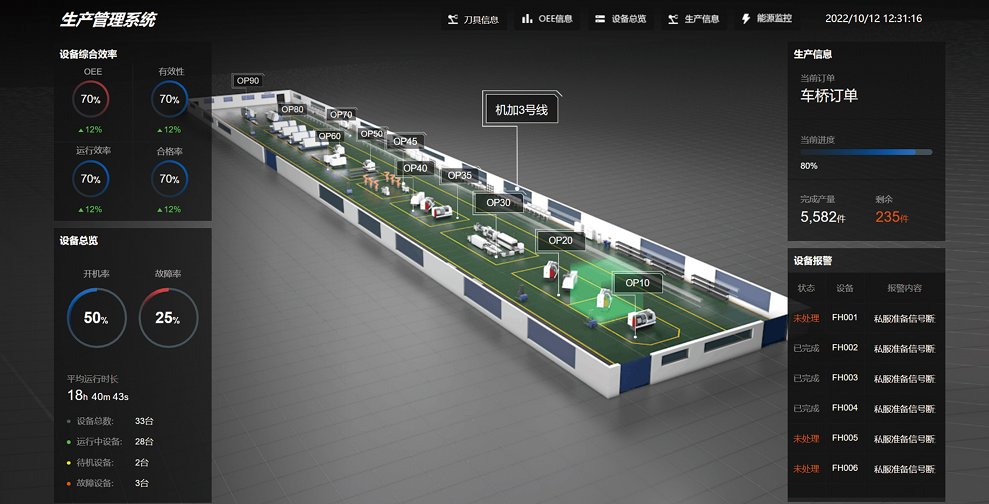

Visualization

With VR vision directly connected to CAD, a simulation of the finished production line will be provided before the product or production line is built, and every change will be reflected in the 3D design model. Immersive visualization and natural interaction will provide more new perspective about the product or new production line, thus contributing more creative solutions and unique ideas.